Healthcare technology continues to evolve with a strong focus on accuracy, safety, and efficiency. From diagnostic machines to patient monitoring systems, medical equipment depends on reliable electrical connections to perform consistently. Among the essential components that support this reliability, circular connectors have become increasingly important for their durability, compact design, and ability to support multiple functions.

Why Circular Connectors are vital in healthcare

Medical equipment is used continuously and often under urgent conditions. Circular connectors provide the secure and stable connections that these devices need. Their shape allows for easy mating and alignment, while their locking mechanisms prevent accidental disconnection. This reliability is critical in devices such as ventilators, infusion pumps, and imaging machines, where uninterrupted operation can directly impact patient outcomes.

Circular connectors also offer the advantage of supporting high pin density in compact spaces. Modern healthcare devices often need to handle multiple signals and power lines within limited dimensions. These connectors make it possible to deliver both performance and space efficiency.

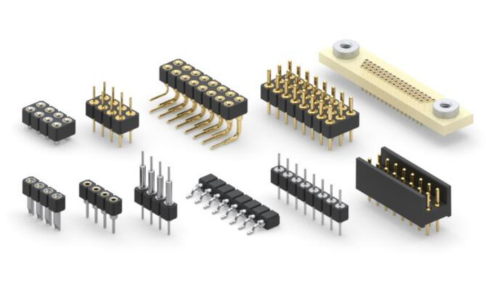

The role of PCB Connectors in compact medical devices

As healthcare technology becomes more compact and portable, PCB connectors are also playing an important role. Many handheld and wearable medical devices rely on printed circuit boards with high-density layouts. PCB connectors enable smooth connections between the board and other components, ensuring accurate data flow in devices such as glucose monitors, portable ECG machines, and diagnostic kits.

By combining circular connectors for external reliability with PCB connectors for internal precision, medical device manufacturers are able to design systems that are both durable and user-friendly.

Sensor connection for real-time accuracy

Medical equipment depends heavily on sensors to provide real-time data. Heart rate monitors, blood pressure devices, and advanced imaging tools all rely on precise sensor connections. Any disruption in these connections could lead to inaccurate readings, which may compromise patient safety.

Circular connectors support these sensor systems by offering shielding against electromagnetic interference and ensuring stable signal transmission. Their secure contacts help maintain accuracy even in environments where multiple devices operate simultaneously. This is particularly important in hospital settings where interference from surrounding equipment can be a concern.

Ruggedized connectors for tough conditions

Not all medical equipment operates in controlled hospital environments. Devices used in ambulances, field hospitals, and emergencies must withstand vibration, shock, moisture, and varying temperatures. This is where ruggedized connectors become essential.

Ruggedized circular connectors are built with strong materials, sealing features, and enhanced durability. They ensure that life-saving equipment such as portable defibrillators and emergency ventilators function reliably even in demanding conditions. Their ability to endure repeated use without failure makes them a trusted choice for critical care systems.

Allied Connectors and healthcare solutions

Manufacturers such as Allied Connectors are contributing to the healthcare industry by offering advanced connector solutions that meet global standards. Their range of circular connectors, PCB connectors, and ruggedized connectors is designed to provide reliable performance in medical equipment where precision and safety are essential.

The role of connectors in medical technology cannot be understated. From ensuring smooth sensor connection to supporting compact PCB layouts and providing rugged solutions for field use, connectors form the backbone of reliable healthcare equipment.